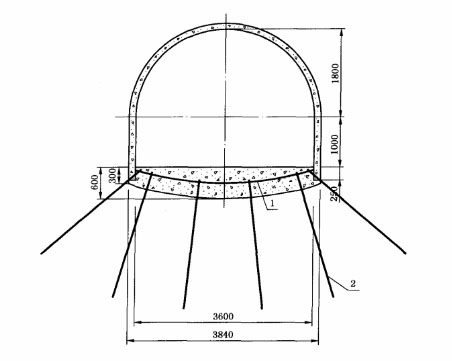

Shanxi Lu'an Group Tunliu Mine exploration way is vertical shaft development. The depth of the bottom level is 588m. The Deputy Shaft is located in the 400m vicinity of the bottom whose warehouse is 75m long, and 595m deep. As early as the second phase in tunneling, it assumed the mine water storage tasks. The section of the internal water storage roadway was designed for straight wall semicircle, and the tunneling section width is 3840mm, height 2920mm.

The original design had been steel mesh and shotcrete lining, then it was optimized for reinforced concrete arching support, and bottom was bunk with concrete. Roadway appeared a large area of the kick drum after one year, which affected the water storage volume and roadway safety seriously.

Roadway floor adopts self drilling anchor bolts technology, anti-bottom arch and reinforced ladders girder for supporting, following are the main supporting technical parameters:

The concrete trans bottom arch thick is 300mm, within arc length is 3650mm, radius 6400mm. The concrete strength grade is C20.

The bottom plate self-drilling anchor bolts adopt vertical anti-bottom arch erection, and the inter-row distance is 1000mm.

Grouting adopts single liquid water slurry, adding water glass as a quick-setting agent. the ladder girders were reinforced with φ18mm rebar.

After the construction of the anti-bottom arch pouring on the roadway floor, self drilling anchor bolts supporting and ladder beam erection were completed, pour the arc inner portion with the concrete which is of the same former degree rating. Finally, reinstate the roadway floor according to the original design.

Tunneling

The Application of Self Drilling Anchor Bolt in the Tunnel Floor Heave Disposal

Date: 2015-05-09view: